TM 55284025423

1119 INSPECT ENGINE HOT END (AVIM) (Continued)

1119

d. Add 11/2 pints of nitric acid (E38) to sodium

dichromate and water solution. Stir solution

with wooden stirring rod (Appendix E).

5.

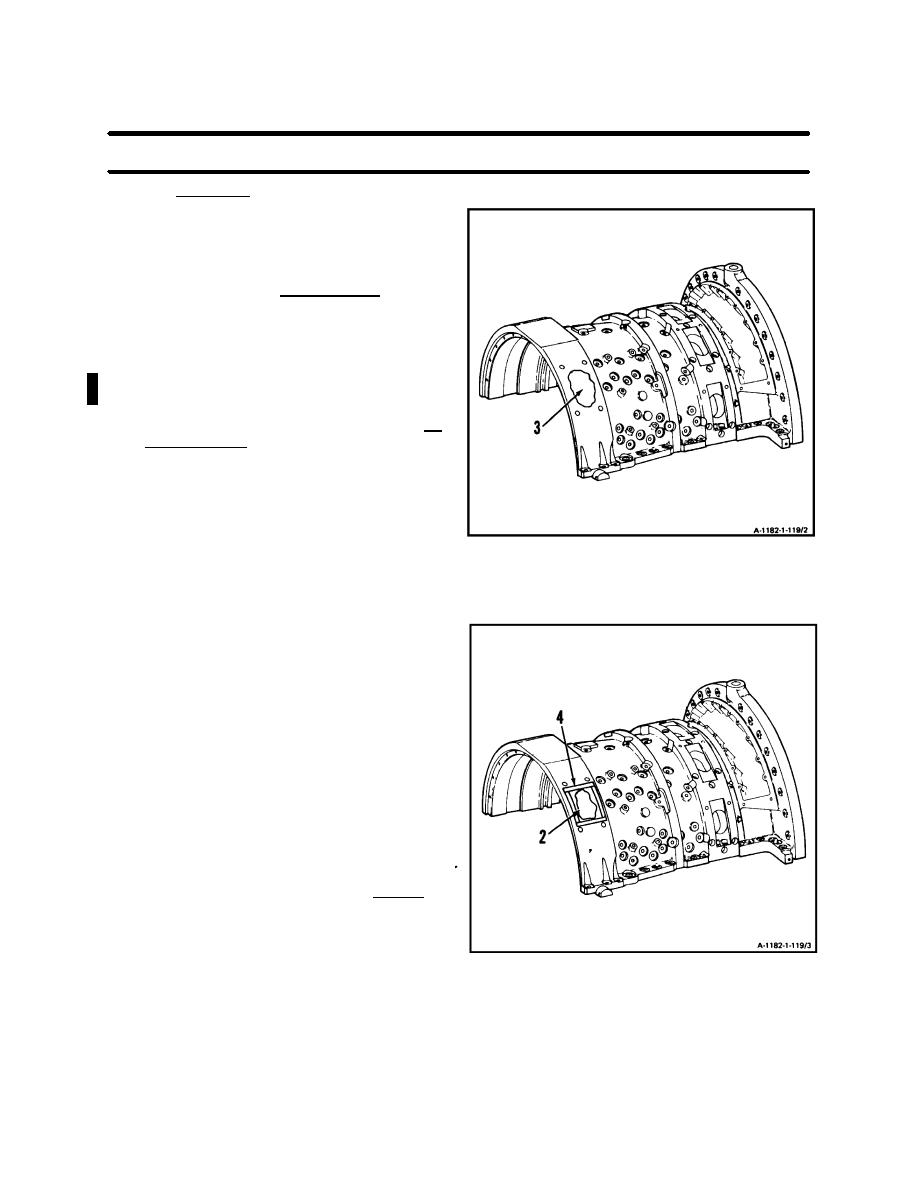

Brush seven coats of solution on bare

magnesium surface (3). Make sure solution

stays on surface for 2 to 5 minutes. Use acid

swabbing brush (E2).

Wipe bare magnesium surface (3). Use

6.

clean lintfree cloth (E26).

6.1. Rinse treated area thoroughly with cold

water.

7.

Dry bare magnesium surfaces (3) from 10

to 15 minutes. Use guntype heater.

8.

Place masking tape (E35) (4) around dam

aged area (2).

8.1. Using an acid swabbing brush (E2) apply

clear synthetic sealant (E12) to affected

area. Smoothly blend sealant with original

coating.

NOTE

A 250 watt reflector heat lamp placed 2 to

4 inches from surface will cure sealant in

approximately 3 hours provided the sur-

face temperature reaches 120_F (49_C)

by the end of cure cycle.

Brush on engine gray enamel (E22) over

9.

damaged area (2). Use acid swabbing brush

(E2).

Let area air dry for a minimum of 4 hours.

10.

11. Remove masking tape (E35) (4).

INSPECT

FOLLOWON MAINTENANCE:

None

END OF TASK

Change 11 1645