TM 55-2840-254-23

106.1

WASH COMPRESSOR (WITHOUT WATER WASH KIT

1-106

P/N 2-200-071-54 INSTALLED) (Continued)

NOTE

Engine water wash should be performed every 50

hours unless in extreme environmental conditions

such as desert-like high sand environments, within

200 miles of volcanic activity, or within ten miles

and 1000 ft agl of salt water environments. Under

those conditions, the engine water wash should be

performed every 25 hours.

NOTE

For best results on engine water wash

procedures, the engine should be washed twice

and rinsed three times. The second wash cycle

ensures that majority of the dirt and grime has

been removed from the engine. The third rinse

ensures that all of the cleaning solution has been

removed from the engine.

NOTE

Currently B & B 3100 (MIL-C-85704, Type I) is

the primary cleaner for Army turbine engines

and remains an approved cleaner for environ-

mental restrictions permit. Where environmental

restrictions preclude its use MIL-C-85704, Type

II and Type IIA should be used. Continue to use

B & B 3100 where not restricted. Approved

Type II and Type IIA cleaners shall be used in

accordance with the existing washing procedure;

however, they are less effective than Type I

cleaners; therefore, more frequent engine washes

may be required to achieve satisfactory results.

Type IIA cleaners do not require dilution with

water.

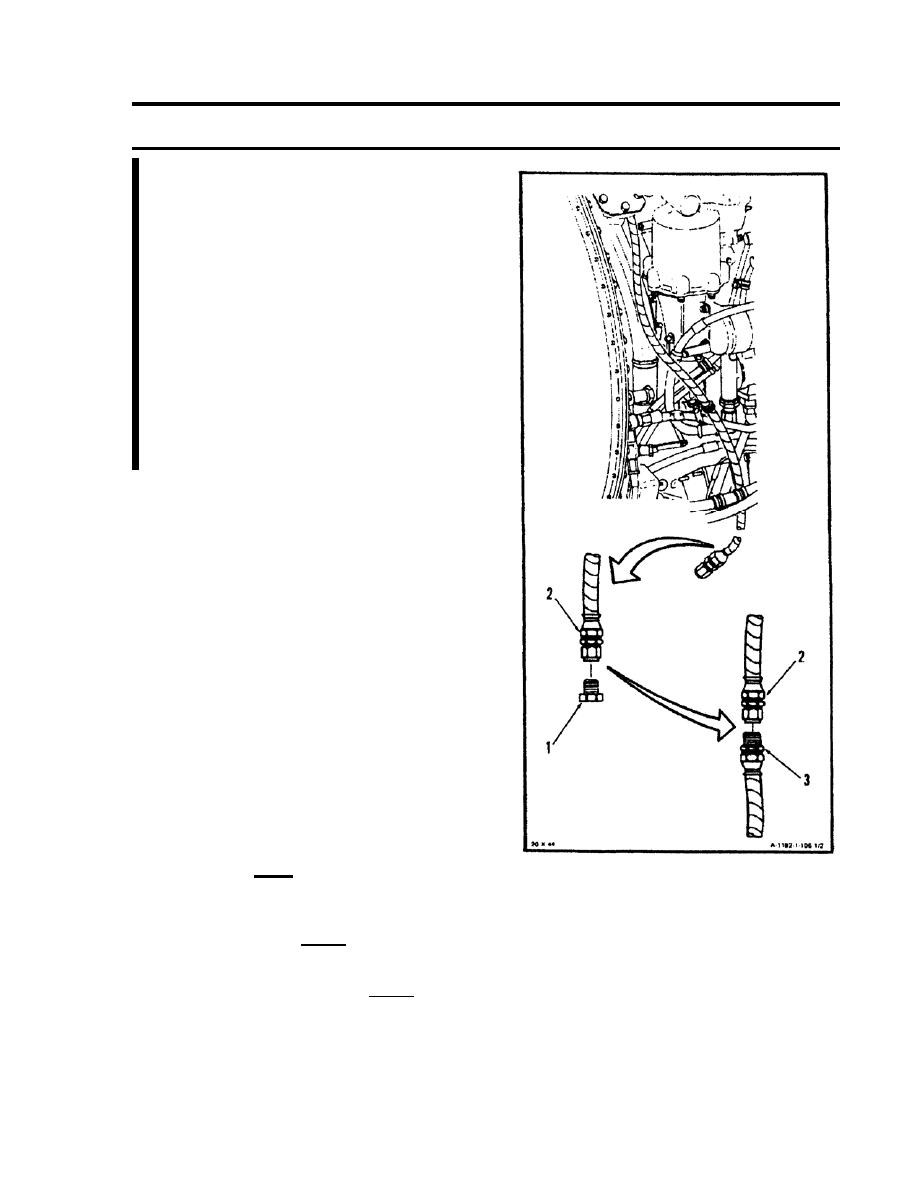

1. Disconnect protective plug (1) from water wash

system hose assembly (2).

CAUTION

Do not exceed 60 psi air pressure or damage

to bleed band actuator diaphragm may occur.

2. Connect air pressure hose (3) with air pressure

regulator and a source of 60 psig to water wash

system hose assembly (2).

3. Adjust air pressure on regulator to 60 psig

maximum to close compressor bleed band.

GO TO NEXT PAGE

Change 12