TM 55-2835-209-23

4-6 REPAIR -WELD FUEL CONTROL LOWER COVER CRACKS (AVIM) (CONT)

1.

2.

3.

Vapor degrease (Task 8-2) fuel con-

trol lower cover using 1,1,1-

trichloroethane (D41).

Dry p art thoroughly with clean, fil-

tered compressed air.

Penetrant test for extent of fatigue

crack.

Liberally apply post-

emulsifiable penetrant solution,

component of penetrant inspection

kit (D27) to area with cotton appli-

cator (D10).

Leave on for 30 min-

utes.

Keep solution wet.

NOTE

If re-welding is required, do

not allow weld width to exceed

2.5 times the thickness of the

parent metal.

13.

Anodize touch up of welded area

(Task 4-8).

FOLLOW-ON MAINTENANCE: None.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Wipe off excess penetrant using

1,1,1-trichloroethane (D41) and ma-

chinery towel (D20).

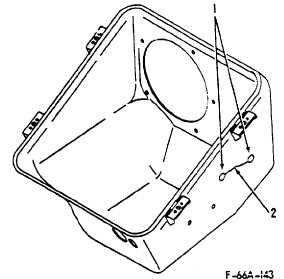

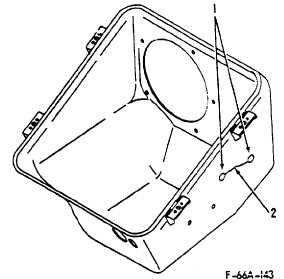

Stop drill crack ends (1) to prevent

further progression of crack (2).

Clean area to be welded with

methyl-ethyl-ketone (D21) and ma-

chinery towel (D20).

Dry part thoroughly with clean, fil-

tered compressed air.

Weld crack using filler rod.

Clean welded area using 1,1,1-

trichloroethane (D41) and machinery

towel (D20).

Dry p art thoroughly with clean,

filtered compressed air.

Penetrant test for cracks in welded

area.

Liberally apply post-

emulsifiable penetrant solution,

component of penetrant inspection

kit (D27) to welded area with cot-

ton applicator.

Leave on for 5 mi-

nutes.

Keep area wet.

Wipe off excess penetrant with

1,1,1-trichloroethane (D41) and ma-

chinery towel (D20).

4-19