TM 5-6115-590-12

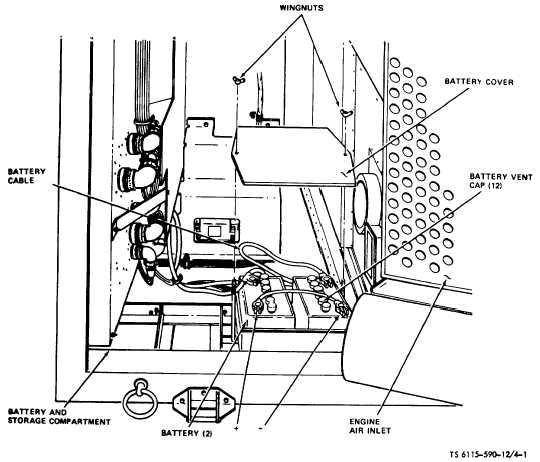

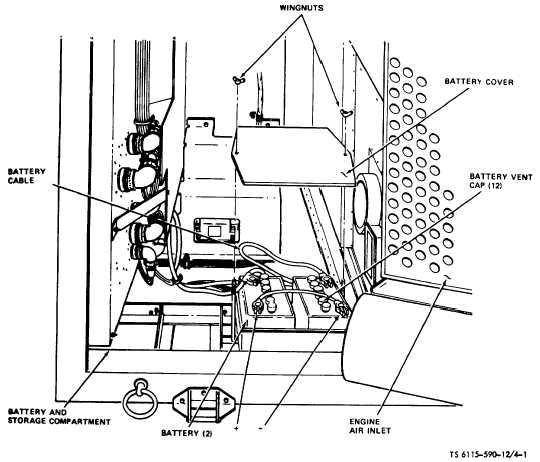

Figure 4-1. Battery Servicing (TS 6115-590-12/4-1).

NOTE

Locations where power plant may be

exposed to high humidity, sand, or dust,

should be avoided whenever possible.

Moisture condenses on power plant parts

and may cause corrosion. Sand, dust,

and dirt shorten life of parts and can

cause mechanical failure.

(2)

Position

the

power

plant

on

any

reasonably level surface, then adjust position to obtain

as near level as possible.

NOTE

Do not operate power unit if front to rear

axis is more than 15 degrees from level

with up to 10 degrees displacement to

either side.

b.

Installation Connections.

(1)

Grounding Procedure. The power unit

shall be grounded in order to prevent shock due to

defective insulation, or external electrical faults. Poor

grounding can endanger personnel, may damage

equipment,

and

can

create

interference

in

communication or electronic circuits. Install one of the

following items as a grounding device:

(a)

Drive a ground rod (fig. 1-15, sheet

7 of 7) to a depth of at least 8 feet. This is the preferred

device which is shipped with the power unit. (An

existing underground pipe may be used in an

emergency.)

(b)

Bury a 1/4 inch thick iron or steel

plate or 1/16 inch thick aluminum or copper plate, 18

inch x 18 inch in size, with a ground cable attached, to

depth of at least 4 feet.

(c)

Position a 1/4 inch thick iron or steel

plate, or 1/16 inch thick aluminum or copper plate,

approximately 18 inch x 18 inch size, on the hard

ground or bedrock beneath the trailer stand or roll the

wheel of a trailer or truck until it comes to rest on top of

the grounding plate.

Change 2

4-2.1