TM 5-6115-590-12

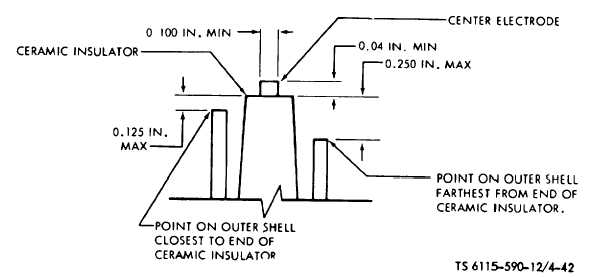

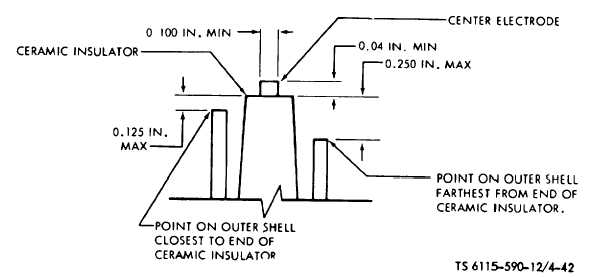

Figure 4-42. Igniter Plug Erosion Limits (TS 6115-590-12/4-42).

(2)

Cleaning and Inspection.

(a)

Clean

relay

with

filtered

compressed air or wipe with a clean rag moistened with

an approved cleaning solvent.

(b)

Visually inspect relay for corrosion,

cracks, damaged threads or other evidence of damage.

(3)

Installation. Install in reverse order of

removal procedure.

j.

Relay (K15).

(1)

Removal. Tag and disconnect electrical

connections to relay (fig. 4-37). Remove four nuts, eight

flat washers, eight lock washers, and four screws.

Remove relay.

(2)

Cleaning and Inspection.

(a)

Clean

relay

with

filtered

compressed air or wipe with a clean rag moistened with

an approved cleaning solvent.

(b)

Visually inspect relay for corrosion,

cracks, damaged threads or other evidence of damage.

(3)

Installation. Install replacement relay in

reverse order of installation.

k.

Current Transformer 400.Hz CT1, CT2, CT3 (fig.

4-37).

(1)

Removal. Tag and disconnect electrical

connections to transformer and electrical leads passing

through the center of the transformer. Remove four

attaching screws and washers and remove transformer

from power chassis.

(2)

Cleaning and Inspection.

(a)

Clean

transformer

with

filtered

compressed air or wipe with a clean rag moistened with

an approved cleaning solvent.

(b)

Visually

inspect

transformer

for

corrosion, cracks, damaged threads, excessive heat or

other evidence of damage.

(3)

Installation.

Install

replacement

transformer in reverse order of removal.

l.

Thermal Relay (three used: S10-A, S10-B, S10-

C) (fig. 4-38).

(1)

Removal. Remove two screws and cover

from relay. Tag and remove electrical leads and bus

bars from relay. Remove two screws, two flat washers

and two lock washers from relay. Remove thermal

relay.

(2)

Cleaning and Inspection.

(a)

Clean relay with compressed air or

wipe with a clean rag moistened with an approved

cleaning solvent.

(b)

Visually inspect relay for corrosion,

cracks, damaged threads, excessive heat or other

evidence of damage.

(3)

Installation. Install replacement relay in

reverse order of removal procedures. m. Shunt R1.

(1)

Removal. Tag and remove electrical

leads from shunt (fig. 4-37). Remove two (2) attaching

screws and washers and remove shunt from power

chassis.

(2)

Cleaning and Inspection.

(a)

Clean

shunt

with

filtered

compressed air or wipe with a clean rag moistened with

an approved cleaning solvent.

(b)

Visually inspect shunt for corrosion,

cracks, damaged threads or other evidence of damage.

(3)

Installation. Install replacement shunt in

reverse order of removal.

n.

Terminal Boards TB5 and TB6 (fig. 4-38 and

4-39).

(1)

Removal. Remove snap on cover from

terminal board. Tag and remove electrical connections

and bus bars from terminal board. Remove

4-92