TM 55-2840-254-23

A. Self-contained system provides lubrication of all engine bearings and gears. Included are provisions to al-

low monitoring of oil temperature, oil level, and metal contamination. Main components are listed and keyed in

following diagrams.

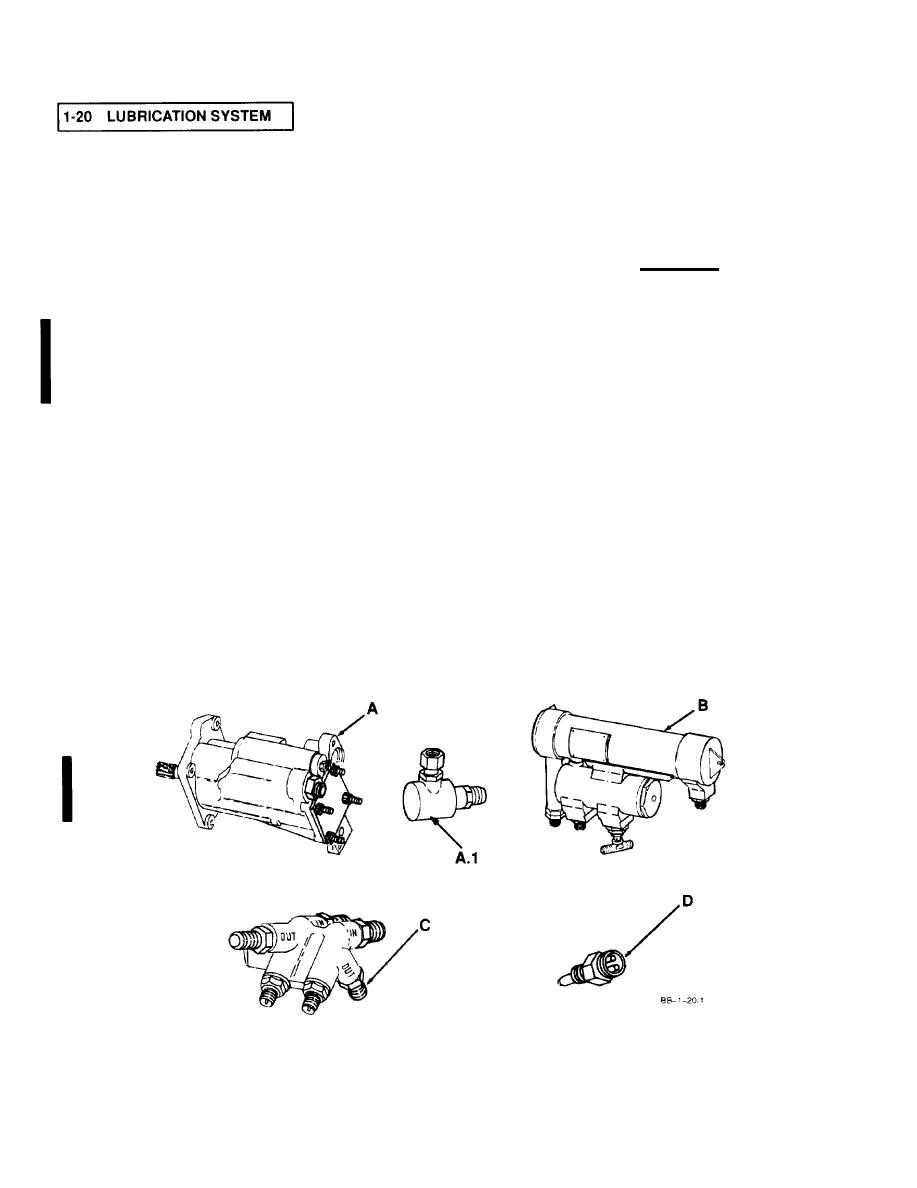

A. MAIN OIL PUMP. Contains three gear-type elements on one common splined shaft. One element sup-

plies oil pressure. The other two return scavenge oil to the Integral oil tank. Provides 50 to 90 psig oil pres-

sure during normal engine operating conditions. Mounts on and is driven by accessory gearbox assembly.

A. 1. CHECK VALVE. Located downstream of oil pump and main oil filter. In this location. any contamination

which may be present in the oil after servicing or from oil pump wear will have to pass through the main oil

filter and therefore will not be able to cause improper operation of check valve. The check valve also pre-

vents oil from oil tank from leaking into No. 1 bearing, past No. 1 seal and overboard through the inlet hous-

ing.

B. OIL COOLER ASSEMBLY. Provides a means of lowering oil temperature. Contains many small diame-

ter aluminum tubes (fuel flow paths) running lengthwise through one large oil flow path. As hot oil passes

over low-temperature fuel tubes some heat is transferred to fuel. Results in higher fuel temperature (de-

sired) and lower oil temperature. Mounts on interstage air-bleed actuator and bracket on right side of com-

pressor housing.

C. OIL TEMPERATURE TRANSMITTER. Provides a means of relaying oil temperature to cockpit indica-

tor. Converts oil temperature to electrical signal. Installs in right side of accessory gearbox.

D. DUAL CHIP DETECTOR. Provides a means to filter and detect metal contamination originating in the

No. 2 or No. 4 and 5 bearing areas, Contains two separate plug assemblies each surrounded by a small

mesh basket (filter). Buildup of chips between fitter and plug assembly can be detected by a resistance

check or by visual inspection.

1-34

Change 10