TM 55-2835-209-23

3-15 INSPECT HOT SECTION COMPONENTS (AVIM) (CONT)

8.

9.

10.

11.

12.

13.

14.

NOTE

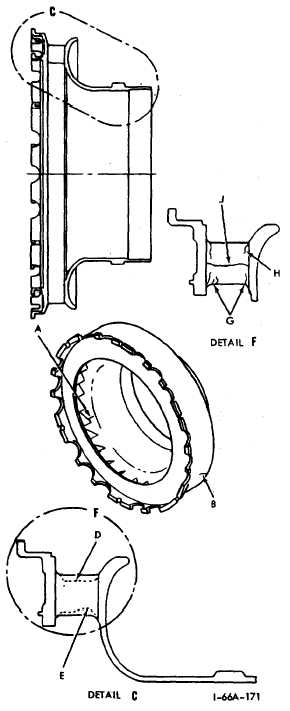

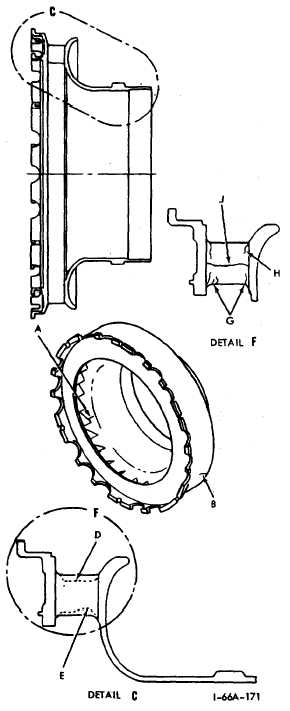

Inspect turbine nozzle as fol-

lows.

Visually inspect for axial cracks in

shroud below vane inner diameter

(reference A).

No cracks allowed.

If cracks are suspected, fluorescent

penetrant per MIL-STD-6866.

Visually inspect for cracks in plat-

form outer diameter (reference B).

No cracks allowed.

Inspect leading edge of vanes (ref-

erence D) for erosion.

Damage

shall not exceed 0.125 inch deep.

Repair erosion (Task 3-16).

Inspect trailing edge of vanes (re-

ference E) for erosion or feather-

ing damage.

Damage shall not

exceed 0.130 inch deep.

Repair

erosion or feathering (Task 3-16).

Inspect trailing edge of vanes (re-

ference G) for cracks. Cracks max-

imum of 0.500 inch in length on six

adjacent vanes or ten non-adjacent

vanes are acceptable.

No other

cracks allowed.

Inspect leading edge of vanes (ref-

erence H) for cracks.

No cracks

allowed.

Inspect vanes (reference J) for

axial cracks.

Cracks in more than

11 vanes, cracks less than 0.350

inch from trailing edge of vanes,

cracks that are open so as to dis-

rupt gas stream or axial cracks

connected in any vane so as to

cause material loss are not accept-

able.

Change 1

3-39