T M

5 5 - 2 8 3 5 - 2 0 9 - 23

3-14 HOT SECTION INSPECTION (1000 HOUR) (AVIM) (CONT)

INSTALLATION

NOTE

Prior to assembly, components

will be visually inspected for

obvious damage.

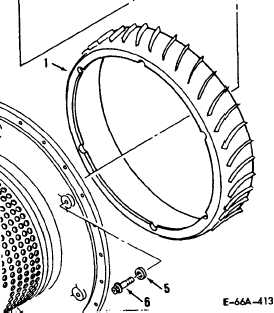

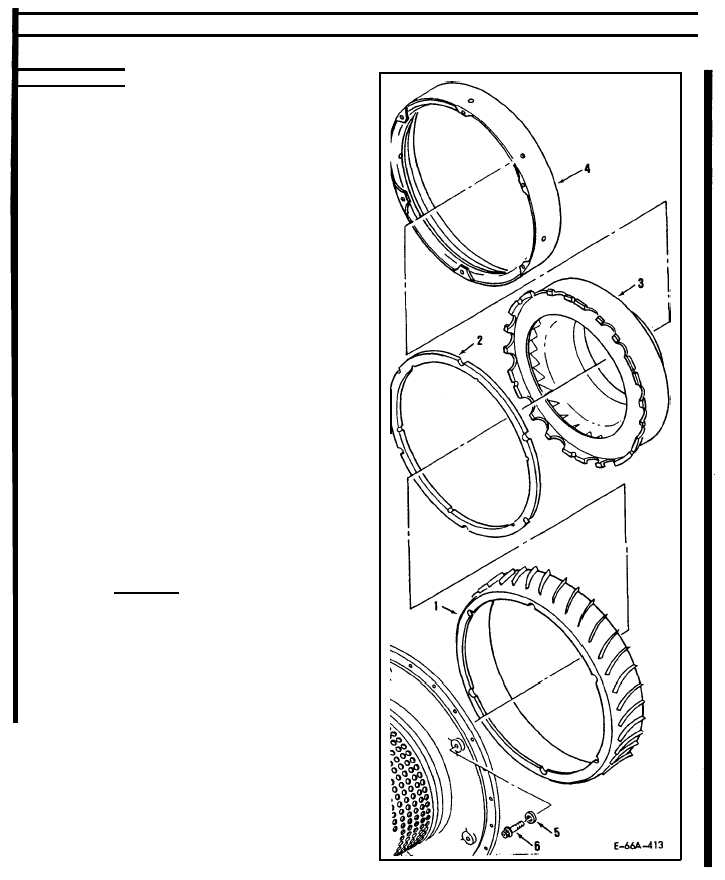

1.

Install compressor airflow deflector

(l).

Ensure alignment marks on com-

pressor airflow deflector and com-

pressor housing are together.

2.

Install same thickness and quantity

of shims (2) recorded in REMOVAL,

step 8.

3.

Install turbine nozzle (3). Ensure

alignment marks on turbine nozzle

and compressor housing are together.

4.

Install airflow deflector (4). En-

sure alignment marks on airflow de-

flector and compressor housing are

together.

5.

Apply antiseize compound (D7) to

threads of bolts (6).

6.

Install washers (5) on bolts (6).

Install bolts.

Torque bolts in an

alternating pattern (180 degrees

apart) 48 to 52 inch-pounds.

7.

Install combustion chamber (Task

3-6).

8. Service lubrication system (Task

6-19).

FOLLOW-ON MAINTENANCE: None.

3-36

Change 1