TM 5-6115-590-12

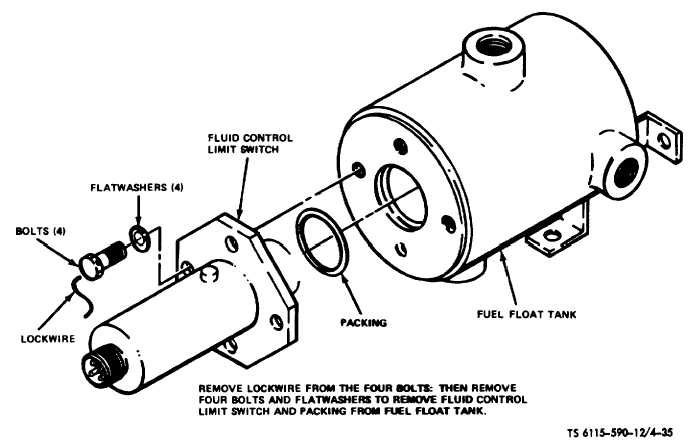

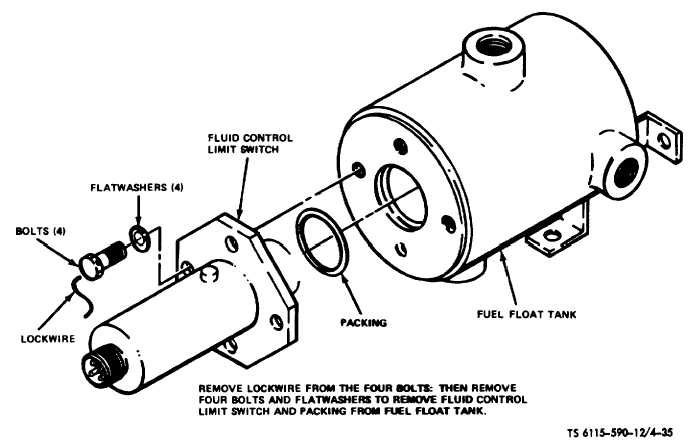

Figure 4-35. Fuel Float Tank Assembly and Fluid Control Limit Switch (TS 6115-590-12/4-35).

c.

Disassembly. Disassemble fuel float tank and

fluid limit switch in accordance with the instructions

contained in figure 4-35.

d.

Cleaning, Inspection and Repair.

(1)

Clean all non-electrical parts with an

approved cleaning solvent and dry thoroughly with

filtered compressed air.

(2)

Inspect hardware for stripping, cross-

threading, or other damage.

(3)

Inspect tank for cracks, dents or other

damage.

(4)

Inspect switch for external damage.

(5)

Replace packing each time tank assembly

is disassembled.

(6)

Replace damaged or inoperative switch.

(7)

If tank is damaged beyond-repair, replace

it.

(8)

Use new hardware as required.

e.

Fluid Control Limit Switch Test. Test the fluid

control limit switch in accordance with the procedures

given on figure 4-36.

f.

Reassembly. Reassemble switch and tank in

reverse order of disassembly as shown on figure 4-35.

g.

Installation.

(1)

Install replacement fuel float tank in

reverse order of removal.

(2)

Install plug in bottom of fuel tank.

4-54. Fuel Float Tank Vent Valve

a.

Removal.

(1)

Remove the two tube assemblies (fig.

4-34) and elbows from vent valve.

(2)

Remove two screws and washers and

remove valve from mounting bracket.

b.

Installation.

(1)

Install replacement valve in reverse order

of removal.

(2)

Install

elbows

and

connect

tube

assemblies.

4-55. Oil Tank Assembly

a.

Removal. Drain all oil from tank assembly (fig.

4-33). Remove tube assemblies from oil tank, loosen

clamp strap on tank cradle, and remove oil tank

assembly from cradle.

b.

Installation.

Install

replacement

oil

tank

assembly in place of cradle and secure with a clamp

strap. Reconnect tube assemblies to tank using new

gaskets. Insure that drain plug is securely tightened.

Refill oil tank.

4-56. Fuel Tank Assembly

a.

Removal

(1)

Remove drain plug from fuel tank (fig.

4-33) and allow all fuel to drain from tank.

4-82