TM 55-2840-254-23

1-117

1-117 STANDARD MAINTENANCE PRACTICES (Continued)

(10) Discard removed packings, cotter pins, retainers, tabwashers, etc.

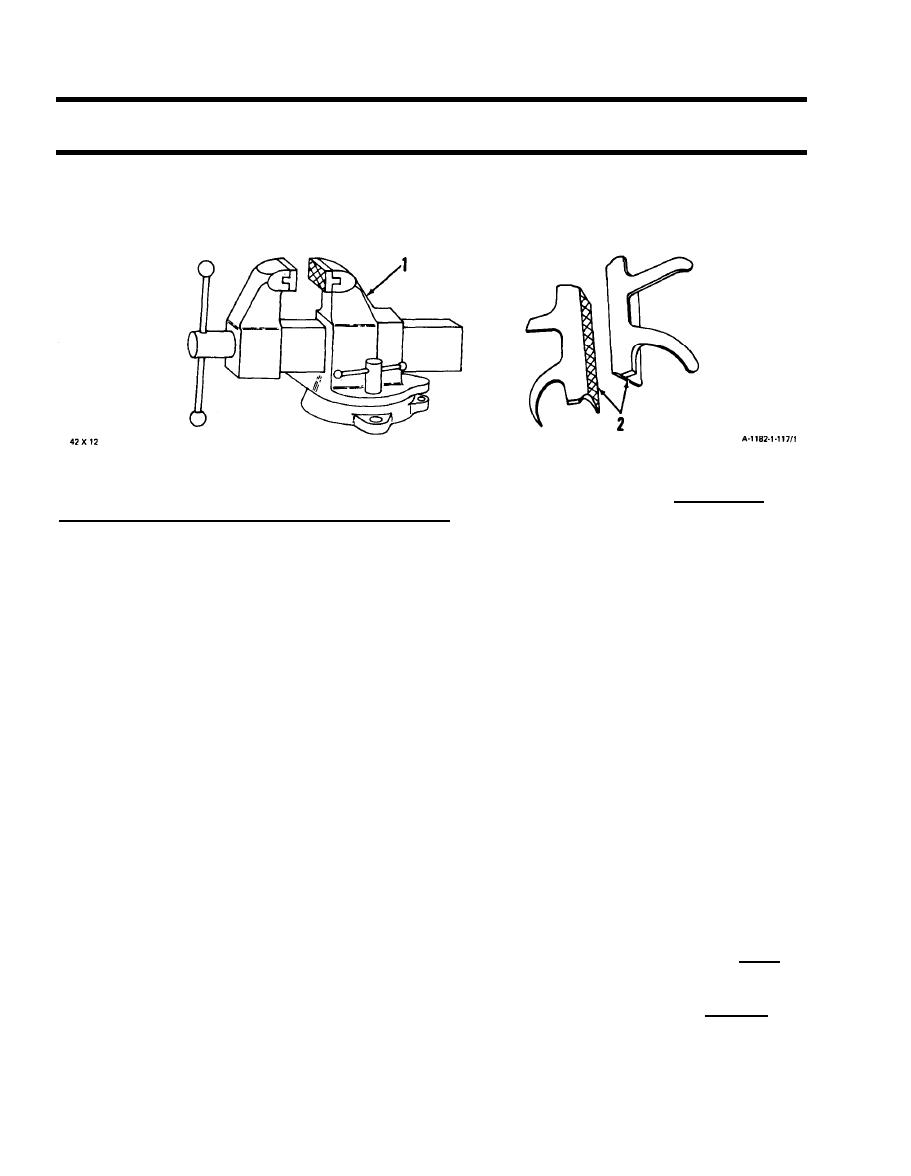

(11) During disassembly tasks, components may be held in vise (1) with soft jaw caps (2) unless task

steps instruct otherwise.

(12) In Disassembly tasks, components are removed and wires and hoses disconnected.

(13) Disassembly procedures reflect the total breakdown of a part as it is authorized. You may not

need to disassemble a part as far as described in the task. Follow the steps to disassemble only as far as

necessary to replace worn or damaged parts.

B. General assembly practices are as follows:

(1) Remove corrosion preventive compounds from parts which are bathed by the engine lubrication

system.

(2) Be sure to install all parts properly as tagged at removal or disassembly. Be sure all necessary

tolerances are met.

(3) Use new packings, cotter pins, retainers, tabwashers, etc.

(4) Coat packings, before installing, in accordance with the following:

(a) Petrolatum (E40) for fuel system packings.

(b) Shortening compound (E46) for lubrication system packings.

(c) Grease (E23) for pneumatic system packings.

(5) When torquing hardware, observe compliance with torque procedures as required in General Main-

tenance Manual (Ref. TM 55-1500-204-25/1).

(6) Tables in paragraph 1-116 provide standard torque limits for general type screws, nuts, and bolts;

pipe thread fittings and plugs; flared tubing nuts; jam nuts and bolts; and stepped studs. The word install

is used when a standard torque is required. If additional tools are required such as crowfoot wrenches, they

are listed in the task INITIAL SETUP. These standard torque values apply only when special torque values

are not specified in procedures in this manual. A special torque will be cited when the words torque to are

used in this manual. Included in the torque tables are the applicable torque wrenches.

1-628