TM 55-2835-208-23

2-17 REPAIR COMBUSTOR LINER (AVIM) (Continued)

2-17

d .

2.

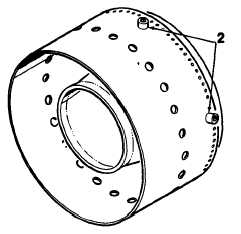

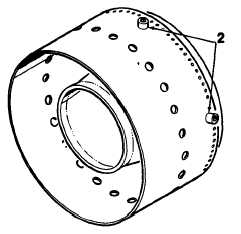

R e p a i r c r a c k s i n b r a z e d j o i n ts

(2) as follows:

W e l d c r a c k u s i n g

welding

rod

(E18)

by

inert

gas

shielded

m e t h o d ( T M 5 5 -

1500-204-25/1).

S t a r t

welding from ends of crack

and

work

toward

c e n t e r.

K e e p w e l d s f l a t o r s l i g h t l y

convex on welded side.

a . W i r e b r u s h o r b u f f r e p a i r

area until bright and clean.

b. Apply

brazing

f l u x ( E 1 2 )

generously to repair area.

C . H e a t a r e a e v e n l y w i t h n e u -

t r a l f l a m e f r o m g a s t o r ch

while

a p p l y i n g a

small

f i l l e t o f

brazing

a l l o y

(E11).

d. Remove

f l u x

r e s i d u e

with

hot water.

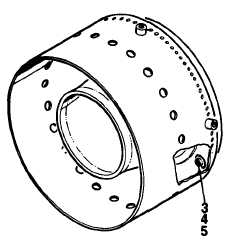

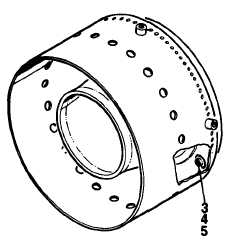

3.

Repair

s t i c k i n g

i g n i t e r p l u g

grommet (3) as follows:

a . A p p l y a f e w d r o p s o f n o n -

carbon

p e n e t r a t i n g

o i l

(E19)

g r o m m e t

( 3 ) ,

spring (4) and washer (5).

b. If grommet remains frozen,

r e p l a c e b y c o l l a p s i n g w i th

p l i e r s

and

tapping

o ut

using a wood drift.

GO TO NEXT PAGE

2-36