ARMY

TM 5-6115-612-34

NAVY AG-320B0-MME-00

8-4. OVERHAUL OF TURBINE ASSEMBLY.

(cont)

f.

Reassembly. (cont)

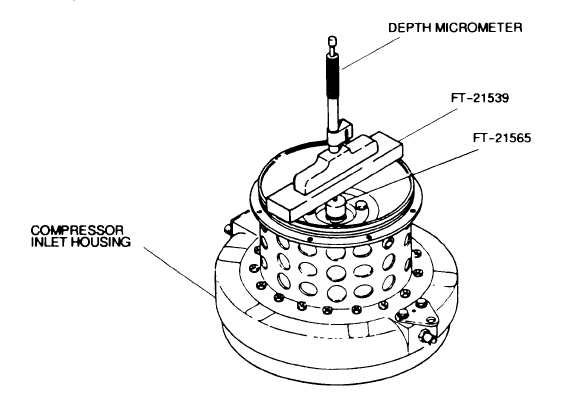

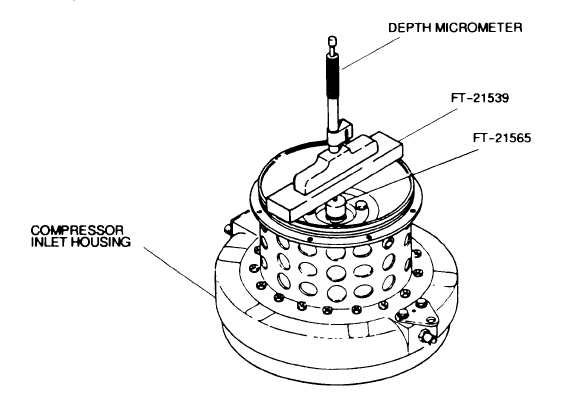

(28) Place fabricated tool (FT-21565, Figure 8-

16) on top of turbine shaft Place fabricated tool (FT-

21539) on top of compressor inlet housing Center hole

over fabricated tool (FT-2156) Take a base reading from

the top of shaft to top of fabricated tool (FT-21539) using

depth micrometer Note the reading. The shaft must be

stretched 0.007- 0.009 inch (0.018-0.023 cm) from the

original reading.

(29) Tighten nut and remeasure shaft length

Repeat procedure until 0.007-0.009 inch (0.018-0.023

cm) stretch has been achieved

CAUTION

Be sure all grinding dust, chips, and

burrs created by balancing operations

are

removed

before

each

step

of

assembly. Failure to remove dust,

chips, and burrs will create excessive

runout when parts are assembled and

may lead to rotating group damage

during engine operation.

(30) Install assembly in bench center On two

center points, maintain runout at 0 002 inch (0 005 cm)

at point K, Figure 8-13

Figure 8-16. Obtaining Reading for Turbine Wheel Shaft Stretch for Final Assembly

Using Fabricated Tools FT-21539 and FT-21565

Change 4 8-39