ARMY

TM 5-6115-612-34

NAVY

AG-320B0-MME-00

84.

OVERHAUL OF TURBINE ASSEMBLY.

(cont)

f.

Reassembly (cont)

(9)

Use wire gage and check clearance

between compressor wheel blade tips and inlet housing.

Adjust shim set (step (5) above) as necessary to attain

clearance of 0 014-0 016 inch (0 036-0 041 cm)

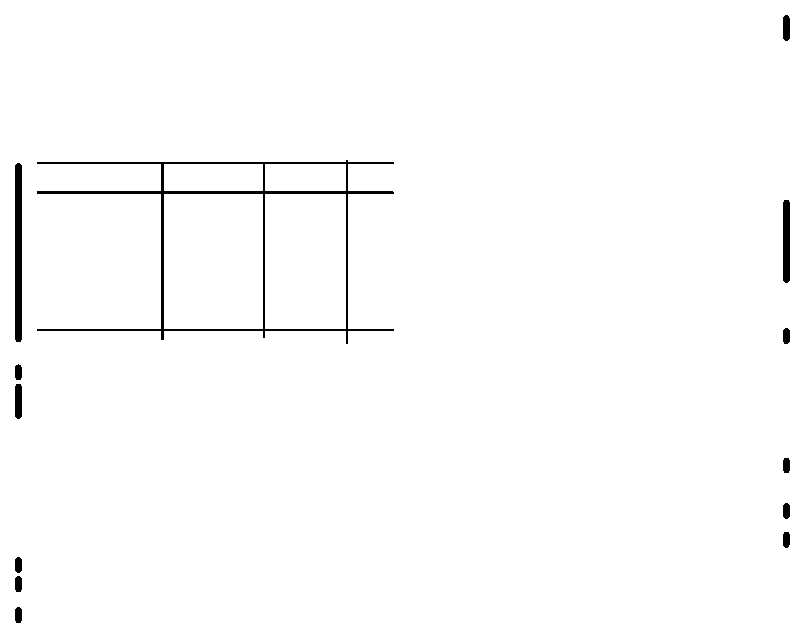

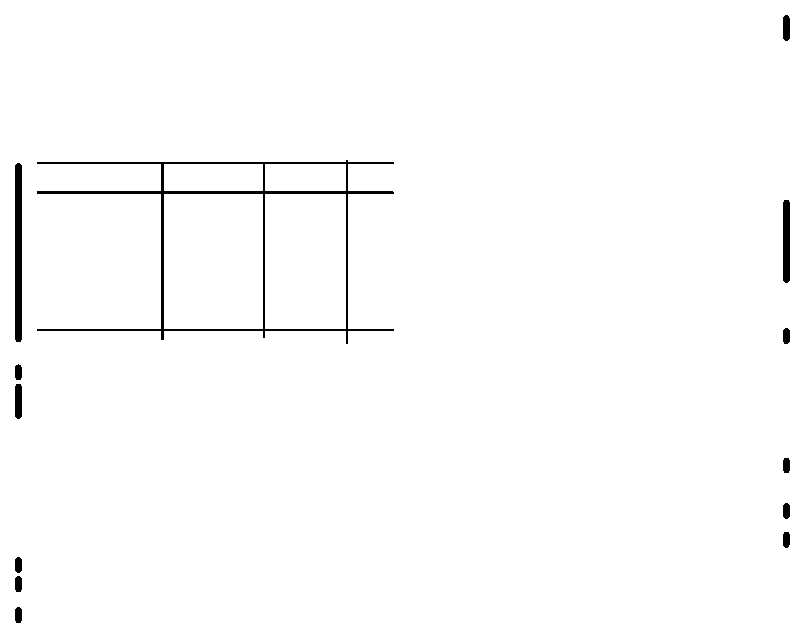

Type of

Thickness

Part No

Qty

Shim/Washer

Bearing Shim

0 024 Inch

101444-1

Metallic Shim

0 002 Inch

101414-4

4 ea

Metallic Shim

0 005 Inch

101414-5

3 ea

Metallic Shim

0 020 Inch

101414-6

2 ea

Wave Washer

101437-1

(10) When

correct

clearance

is

attained,

install

production bearing (37, Figure 8-6) in step (1) Repeat

steps (2) and (3) Ensure that bearing retainer nut (40) is

positioned to allow tabs of tab washer (38) to be bent

Repeat steps (4) thru (5) Install preformed packing (39).

Coat outside diameter of bearing housing at packing and

mating surface of compressor inlet housing with

petrolatum, VV-P-236

CAUTION

DO NOT bend tabs on washers (35)

(11) Using jackscrews as a guide and to keep

shims in place, place correct shim stack (37) and bearing

housing (36) in compressor inlet housing (3). Secure

with washers (35) and bolts (34). Torque bolts to 70-88

inch pounds (7.91-9 04 Nm). Bend tabs on tab washer

(38). Lockwire using MS20995-C32 lockwire.

(12) Install labyrinth seal (29) on back of

compressor wheel (33)

WARNING

To prevent injury, ensure that insulated

gloves are worn when handling dry Ice

and cold parts

CAUTION

To prevent engine failure, ensure that retaining ring (30)

that secures oil passage plug (31) is correctly Installed

(13) Install preformed packing (32) on oil

passage plug (31) Secure in place in diffuser (2) with

retaining ring (30) Ensure that retaining ring is under

retaining groove

CAUTION

If diffuser (2) drops into place without heating and

cooling, replace diffuser

(14) Place diffuser (2) In solution of dry ice and

alcohol for approximately 15 minutes. Use soft flame

and heat outside of inlet housing.

(15) Remove diffuser from solution and Install in

compressor inlet housing (3) Ensure that oil tube holes

and bolt holes are alined.

(16) Install bolts (13) in the 1, 4, 7, 10, 13, and

16 positions. (See Figure 8-7.) Secure with washers (11

and 12, Figure 8-6) and nuts (10). Torque to 74-79 Inch

pounds (8.36-8.93 Nm)

8-36 Change 4