TM 5-6115-590-12

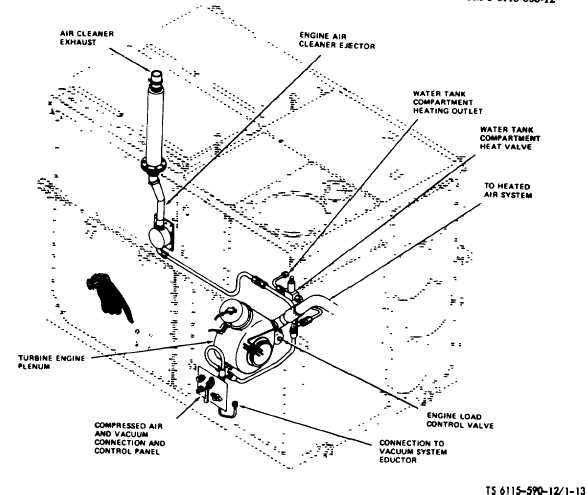

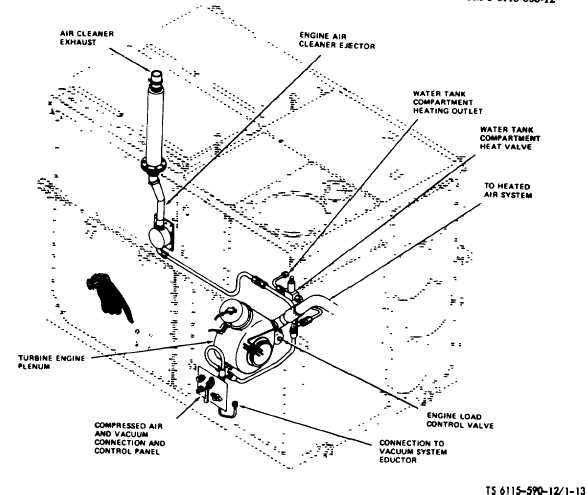

Figure 1-13. Compressed Air System. (TS 6115-590-12/1-13).

(12)

Four conditioned air duct clamp assemblies

used to join the air conditioning duct assemblies

together as required for additional length.

(13)

One divider panel to separate the conditioned

air outlet compartment.

(14)

One vacuum hose assembly for connection of

the power plant vacuum system to other elements of the

MUST hospital that require vacuum service

(15)

One external fuel filter/separator assembly for

filtering inlet fuel to the power plant.

(16)

One fuel hose assembly for connecting the

fuel outlet of the filter/separator to the power plant.

(17)

One fuel hose assembly for connecting the

fuel source to fuel inlet of the filter/separator.

(18)

One fuel hose assembly for extending the

inlet hose from the fuel source to the filter/separator.

(19)

One water recirculating hose to permit the

circulation of water to prevent freezing.

(20)

One cable adapter for connecting two standby

cables together to gain added length when required.

(21)

One ground rod for connecting the power

plant to earth ground.

(22)

One anti-icing hose for the engine air filter de-

icer. (See item 7 of fig. 1-15, sheet 3 of 7).

1-6. Differences Between Models.

This manual covers Power Plant, Utility, Gas Turbine

Engine Driven, AiResearch Co. Model PPU85-5, Libby

Welding Co. Model LPU-7, Amertech Corp. Model

APP-1, and Hollingsworth Model JHTW10/96. This

manual reflects the configuration of the Hollingsworth

Model. PIP-1-80-08-007 is to be installed on the

AiResearch Model, the Libby Welding Model, and the

Amertech Model which will bring these models (except

for

minor

differences),

up

to

the

Hollingsworth

configuration. The Hollingsworth power plant has a

different source of supply for the evaporator and

condenser fan motors, heat control valves for heating

(air conditioning), and for the water pumps.

Change 6

1-21