TM 1284025223

54 INSPECT ACCESSORY GEARBOX ASSEMBLY (Continued)

54

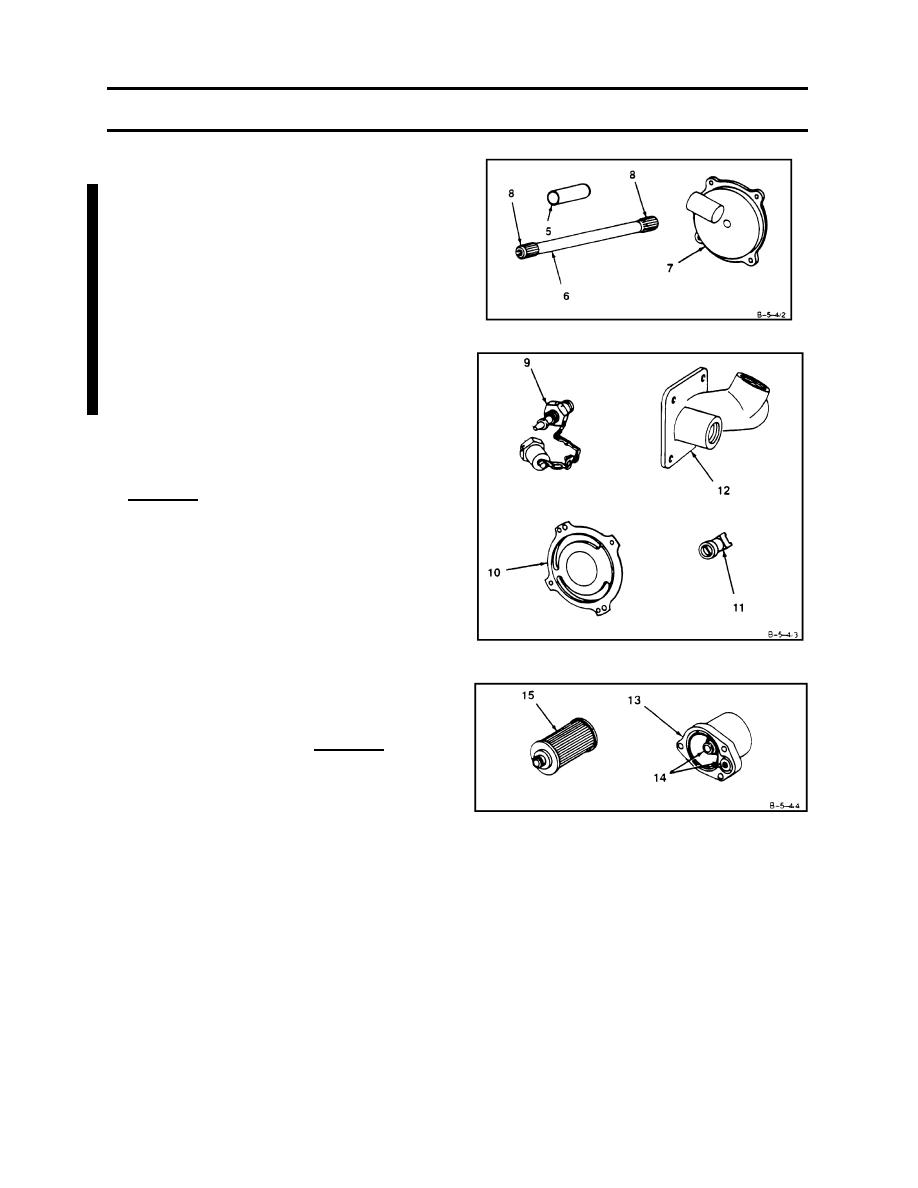

4. Inspect spacer (5), gearshaft (6) and

(7) using fluorescentpentrant (Ref.

TM 1150033523). Parts requiring

fluorescent penetrant inspection will

be final cleaned, prior to inspection, with

NPropyl Bromide (Vapor degreasing only)

(Item E74, Appendix C),

DS108 (Item E75, Appendix C), Electron

(Item E76, Appendix C), or Positron (Item

E77, Appendix C). DS108, Electron or

Positron must be followed by an acetone

(Item E1, Appendix C) or Isopropyl Alcohol

(Item E78, Appendix C) rinse or wipe.

Parts must be dried until there is no visible

solvent residue before applying penetrant.

There shall be no cracks.

5. Inspect gearshaft (6). Inspect splines (8) (Ref.

Task 1109). There shall be no wear deeper than

0.007 inch on splines (8).

6. Inspect oil sampling drain cock (9), oil

scavenge housing (10), relief valve (11), and

collector (12).

There shall be no cracks.

7. Inspect oil filter cover assembly (13).

There shall be no cracks.

a.

There shall be no nicks, dents, or

b.

scratches deeper than 0.010 inch on

packing groove (14).

8. Inspect filter element (15). There shall be no

contamination. If contamination is found,

inspect contaminated oil system (Ref.

Task180).

FOLLOWON MAINTENANCE

None

END OF TASK

Change 1

521