TM 1-2840-252-23-2

4-50

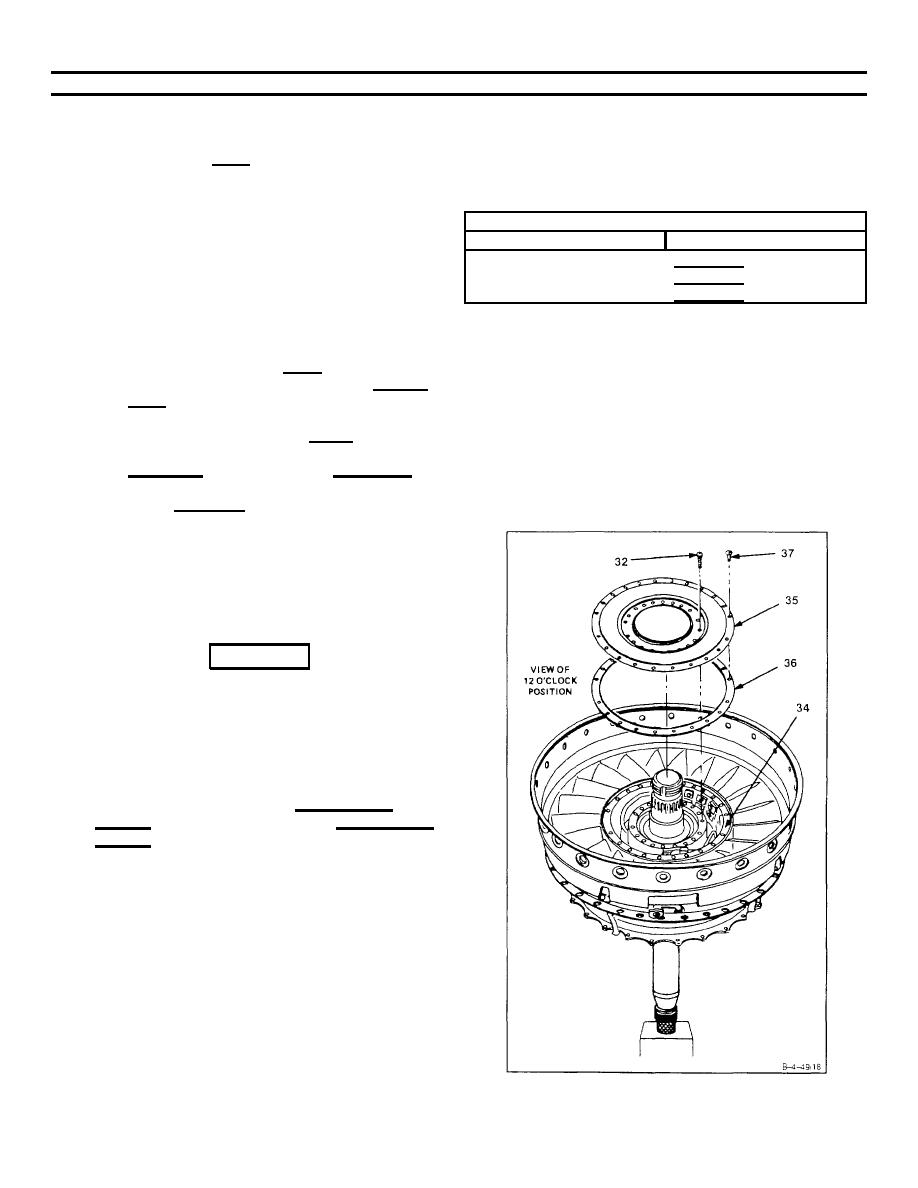

INSTALL FOURTH STAGE POWER TURBINE NOZZLE (AVIM) (Continued)

4-50

NOTE

If Dimension G is 0.001 inch or greater, proceed to

step 27.

NOTE

SHIM SELECTION TABLE

PART NUMBER

SHIM THICKNESS

To maintain axial clearance between screw heads

2-141-422-01

0.010 inch

(outer circle) and fourth turbine rotor blade rivet

2-141-422-02

0.020 inch

heads, clearance should be held as close to

2-141-422-03

0.040 inch

minimum as possible.

j.

If required, select shim from shim selection

table to a maximum of 0.080 inch. Add shim at

outer flange to achieve clearance of 0.001 to

0.050 inch at inner bolt circle mounting surface.

Example If dimension G is -0.039 inch, select

shim Part No 2-141-422-03. Clearance will be

0. 001 inch. If dimension G is -0.019 inch,

select shim Part No 2-141-422-02. Clearance

will be 0.001 inch.

26.

Install shim (36), selected in previous step j on inner

bolt circle on aft face of fourth turbine nozzle

assembly (34).

27.

Coat 20 bolts (32) and 22 new screws (37) with anti-

seize compound (E6).

CAUTION

In following step 28, be sure to use 22 new screws.

Used screws could break and cause damage to

engine. Outer screws are to be torqued first to

reduce breakage.

Install heat shield (35),22 screws (37) and 20 bolts

28

(32). Torque screws (37) to20 to 25 inch-

pounds, then torque bolts (32) to70 to 95 inch-

pounds. Lockwire screws (37) and bolts (32). Use

lockwire (E33).

GO TO NEXT PAGE

4-276