TM 55-2840-254-23

1-107 TEST ENGINE (AVIM) (Continued)

1-107

NOTE

In the following step, SHP required should be obtained from the preceding

Maximum Trim Versus Ambient Temperature graph located at beginning of this

paragraph.

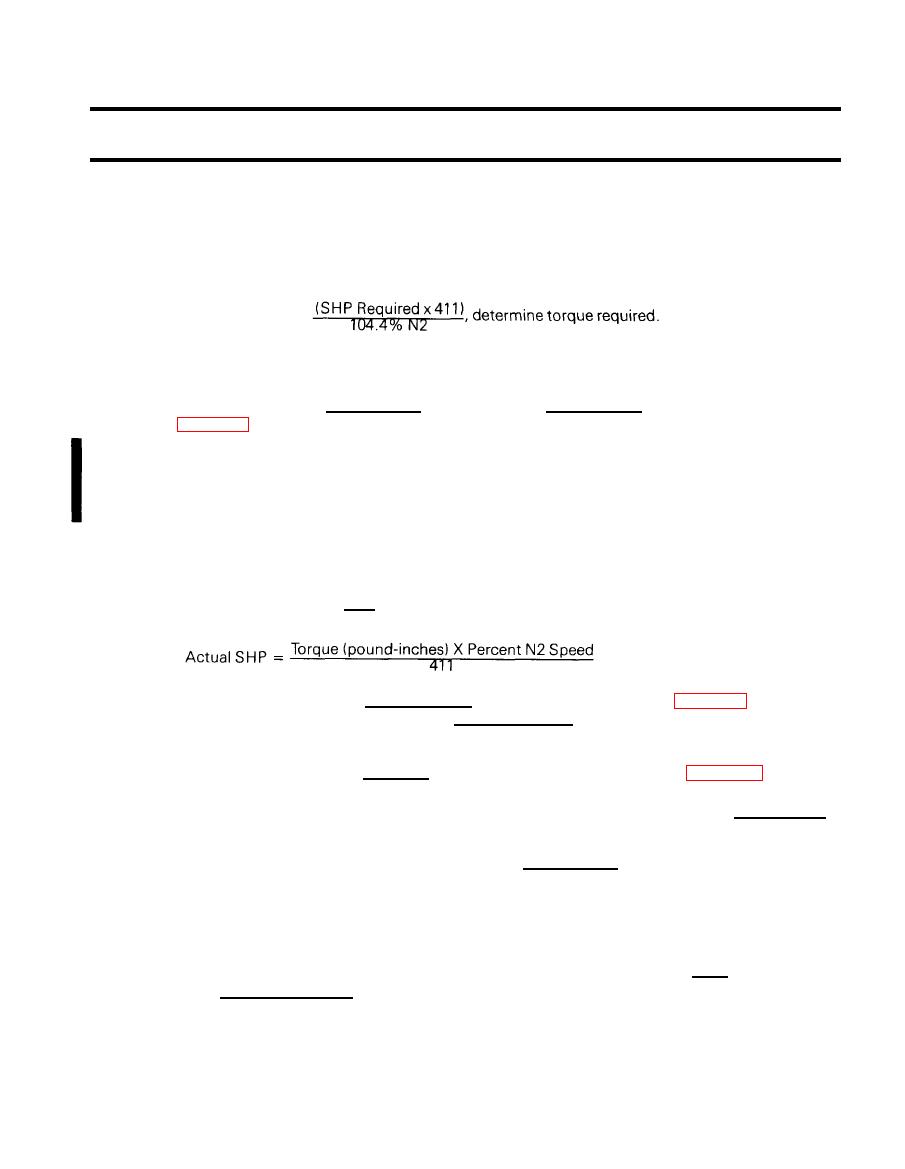

a. Using formula, Torque =

NOTE

If N2 speed exceeds 104.4 percent at steady state or 109.6 percent transient, Ref.

NOTE

During cold weather operation, if maximum trim power is limited by maximum

torque, adjust trim.

b. Calculate actual SHP

To determine actual SHP from test stand indications, multiply torque (expressed in pound-inches) by

percent N2 speed, divided by 411. Obtain torque value used in this computation from water brake

torque system. Example:

c. Check that PTIT does not exceed 1630F (889C) at any time. If exceeded, Ref. Task 1-32 and 1-93.

PTIT along this Iine should normally exceed 1600F (871C).

d. Advance N1 master hydronic control until torque required in preceding step a. is obtained. Check

that N1 speed does not exceed 10zrcent. If exceeded determine cause ( Ref, Task 1-71).

e. Adjust fuel control maximum power trim, as required, to produce shaft horsepower of + 50/-0 SHP

at the throttle stop. Record a full reading.

f. If necessary, increase N2 governor lever travel to obtain 104.4 percent N2 speed. Record adjustment

made and tag fuel control.

NOTE

In following step, for purposes of setting maximum power trim speed

screw, it is permissible to operate engine up to, but not in excess of, 4500

compensated S H P.

GO TO NEXT PAGE

Change 4

1-479