1-93 lNSPECT ENGINE HOT END (AVIM) (Continued)

1-93

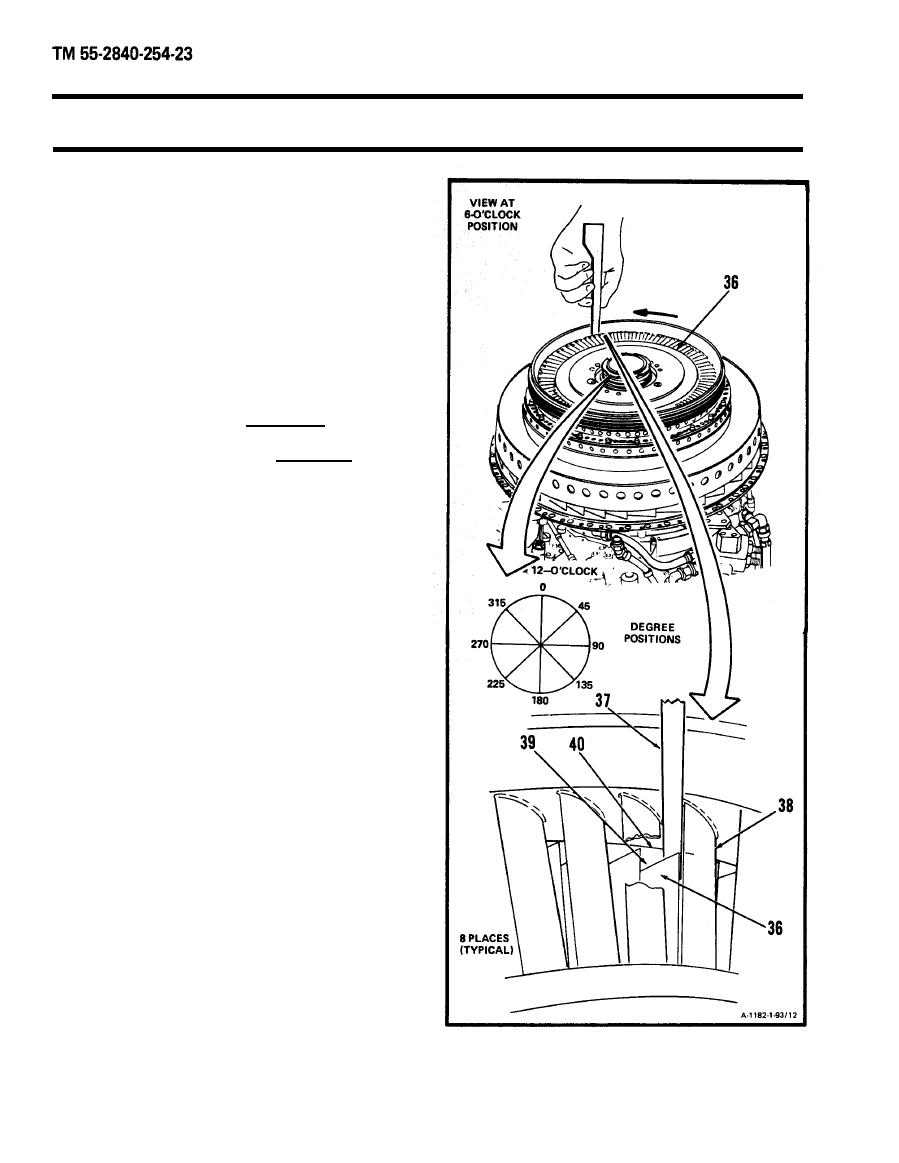

5. Measure first turbine disc assembly (36) tip

clearance at 0, 45, 90, 135, 180, 225, 270,

and 315 degree positions as follows:

a. Insert thickness gage (Appendix E) (37) be-

tween second turbine nozzle vanes (38) and

between blade tip (39) and turbine rotor case

inside diameter (40).

b. Rotate first turbine disc assembly (36)

counterclockwise one revolution for each

check.

c. Tip clearance shall be 0.019 inch minimum.

d. If tip clearance is less than 0.019 inch repair

first turbine rotor case (Ref. Task 4-70).

GO TO NEXT PAGE

1-322