ARMY

TM 5-6115-612-34

NAVY

AG-320B-MME-00

8-4. OVERHAUL OF TURBINE ASSEMBLY.

(cont)

a. Disassembly (cont).

(6)

Place turbine assembly in fabricated tool

(FT-21616, Figure 8-8). This will secure the turbine

wheel (20, Figure 8-6) to prevent rotation.

(7)

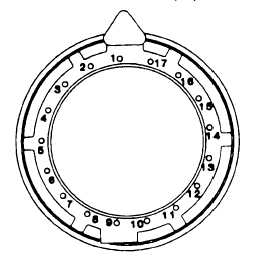

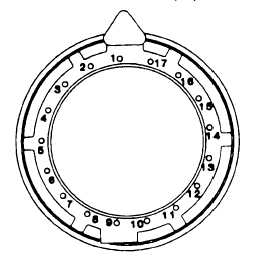

On front of compressor inlet housing (3),

remove nut (10) and washers (11 and 12) that secure

bolts in the 1, 4, 7, 10, 13, and 16 positions (see Figure

8-7) Remove bolts (13, Figure 8-6) from diffuser (2).

WARNING

To prevent injury, ensure that insulated

gloves are worn when handling dry Ice

and cold parts.

(8)

If necessary, place dry ice in diffuser. Wait

approximately ten minutes or until diffuser is well frosted.

Use soft flame to heat outside of compressor inlet

housing Carefully pull diffuser out of housing.

CAUTION

Care should be taken not to damage

shaft. Once drill penetrates nut, STOP

DRILLING!

(9)

Using a 0.125 inch ( 32 cm) drill bit, drill

out staked portion of nut.

NOTE

Speed pickup nut is staked in place.

Once removed, it is NOT reusable.

(10) Using fabricated tool (FT-21368, Figure

8-9) remove and discard speed pickup nut (14, Figure 8-

6)

CAUTION

To remove the turbine wheel, it may be

necessary to use a non-metallic hammer

Damage to the turbine wheel may occur.

NOTE

The turbine wheel assembly consist of

turbine wheel (20), labyrinth seal (19),

and bearing (18)

(11) Remove and discard retainer nut (15) and

key washer (16) Remove turbine wheel assembly from

compressor inlet housing (3)

(12) Remove two antirotation pins (17) from

turbine wheel assembly

(13) Using a bearing puller, remove bearing (18)

from turbine wheel (20) Discard bearing

(14) Using a bearing puller, remove labyrinth

seal (19) from turbine wheel (20) Inspect labyrinth seal

(19) for damage.

Figure 8-7. Compressor Inlet Housing Bolt Patter

Change 4 8-21