TM 1-2840-252-23-2

4-62

INSTALL SECOND TURBINE NOZZLE, SPACER, CASE, AND BUMPER

4-62

(AVIM)

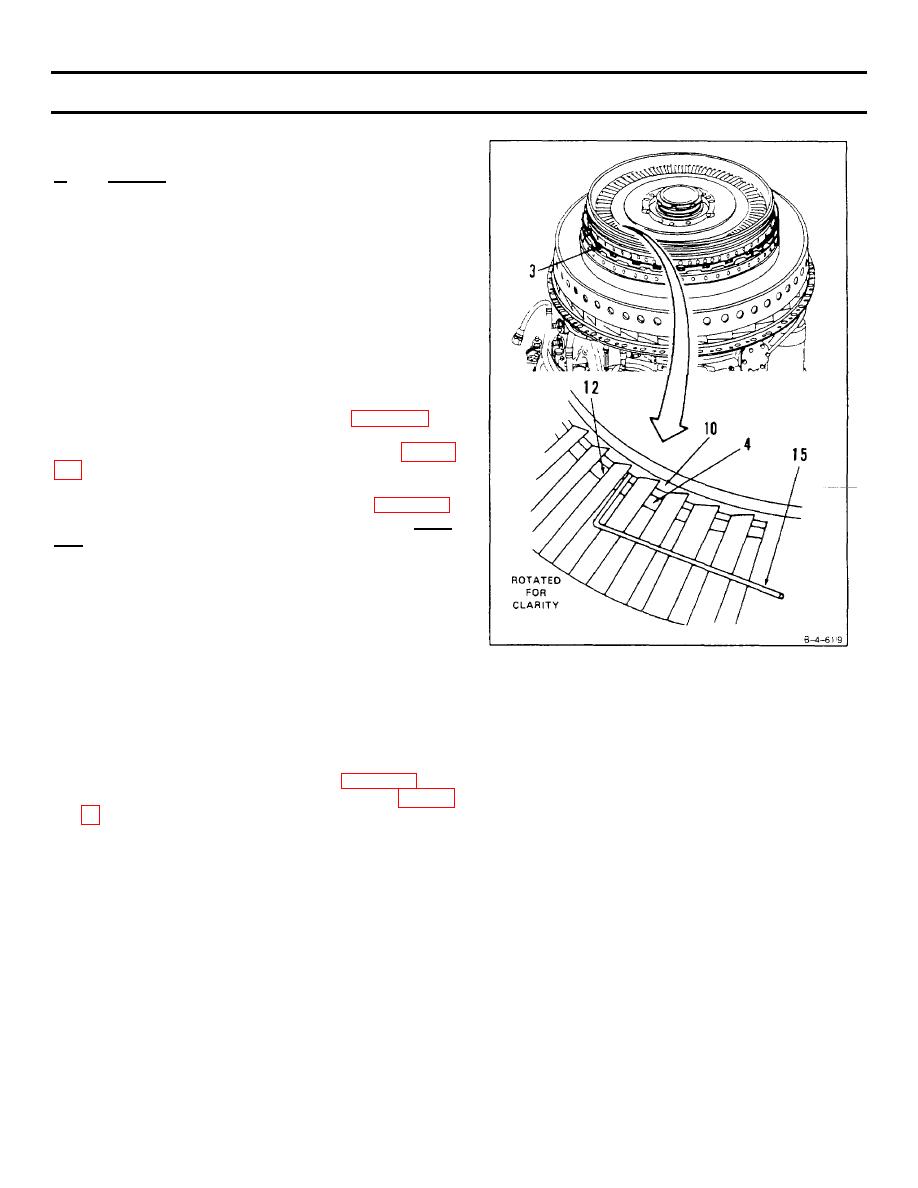

Check axial clearancebetween first turbine disc

13.

assembly (4) and second turbine nozzle (10). Use

053 inch bent wire gage (Appendix E) (15) inserted

0.

through second turbine nozzle vanes (12).

INSPECT

14.

If axial clearance is acceptable, omit step 15.

If axial clearance is not within limits, do all steps.

15.

If axial clearance cannot be obtained, recheck first

turbine disc assembly installation procedure as

follows:

a.

Remove second turbine nozzle (Ref. Task 4-58).

b.

Remove first turbine disc assembly (Ref. Task 4-

c.

Install first turbine disc assembly (Ref. Task 4-67).

Maintain as close to minimum clearance of 0.150

inch

as possible between first turbine disc assembly and

first turbine nozzle.

d.

Repeat steps 4 thru 13.

e.

If axial clearance still cannot be met, replace parts

as

necessary.

16.

Lockwire 24 bolts (3) Use lockwire (E32).

INSPECT

FOLLOW-ON MAINTENANCE

Install Second Turbine Disc Assembly (Task 4-57).

Install Combustion Section and Power Turbine (Task 3-

Service Engine Oil System (Task 1-68).

END OF TASK

4-360